OO-R-2853

3.12.4 Vibrating mechanism. A variable frequency vibrating mechanism,

providing not less than two speeds or two amplitude selections, shall be

provided. The vibrating mechanism shall provide a frequency of not less than

1400 vibrations per minute (vpm). When operating at the manufacturer's

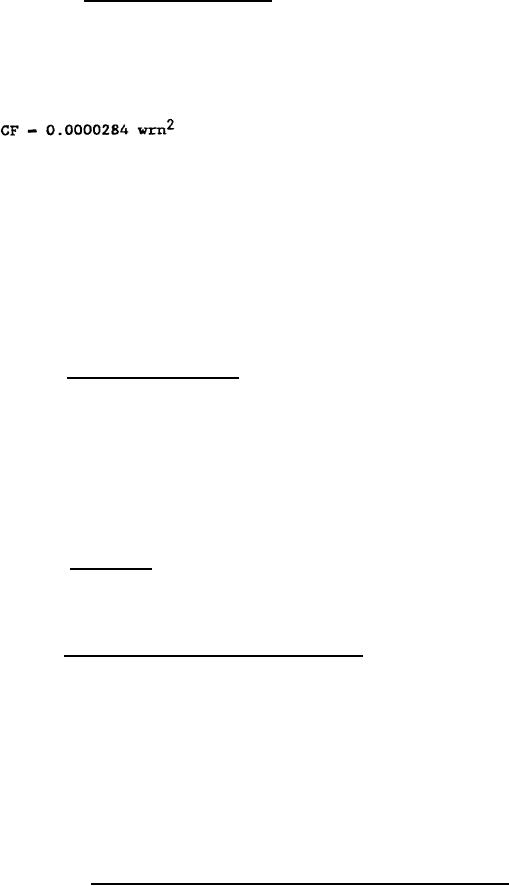

recommended maximum continuous frequency, the centrifugal force (CF) generated

by the vibrating mechanism shall be not less than 23,000 lb (10 432 kg). The

following formula shall be used to compute CF requirement specified herein:

where,

centrifugal force

CF

-

w

-

weight of eccentric revolving body in lb

mean radius in inches

r

-

number of revolutions per minute (rpm)

n

-

All rotating shafts shall be mounted on heavy-duty antifriction type bearings.

The vibrating mechanism shall be driven by hydraulic power furnished by the

roller's engine. Controls for all functions of vibratory modes shall be located

in the operator's station.

The roller shall be provided with an operator's

3.13 Operator's station.

station, furnished with all controls and applicable accessories/instruments (see

3.11.1). The roller shall be furnished with a ROPS with canopy, conforming to

SAE J1040, and a padded operator's seat with a restraint system conforming to

SAE J386. All instruments shall be visible from the normal operating position.

All controls shall be within reach of the operator when in the normal operating

position. Steps or ladder rungs and handholds shall be furnished as necessary

to provide safe and easy access for the operator to the station. The station

deck and steps shall have an antiskid surface. The station shall be isolated

from the vibrations generated by the vibrating mechanism.

3.14 Toolbox. A tool storage box or compartment of sufficient size to hold

any tools as required to perform daily operations shall be furnished with each

roller. When daily operation of roller may be completed without tools, a

toolbox is not required.

3.15 Lifting and tiedown attachments. When specified (see 6.2), the roller

shall be equipped with lifting and tiedown attachments. Lifting and tiedown

attachments shall conform to type II or type III of MIL-STD-209. Lifting

attachments shall be designed to preclude the use of spreader bars. A

nonferrous transportation plate shall be provided and mechanically attached to

the roller. Transportation plates shall be inscribed with a diagram showing the

lifting attachments and lifting slings, the capacity of each attachment, and the

required length and size of each sling cable. A silhouette of the item

furnished showing the center of gravity shall be provided on the transportation

plate. Tiedown attachments may be identified by stenciling or other suitable

marking. Tiedown marking shall clearly indicate that the attachments are

intended for the tiedown of the roller on the carrier when shipped.

3.15.1 Air transportability - construction equipment. When specified (see

6.2), the roller shall meet the air transportability dimensions and weight

limits with a half tank of fuel. If necessary, dimension and weight limits may

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business